What is Welded Wire Mesh and Its Uses in Construction?

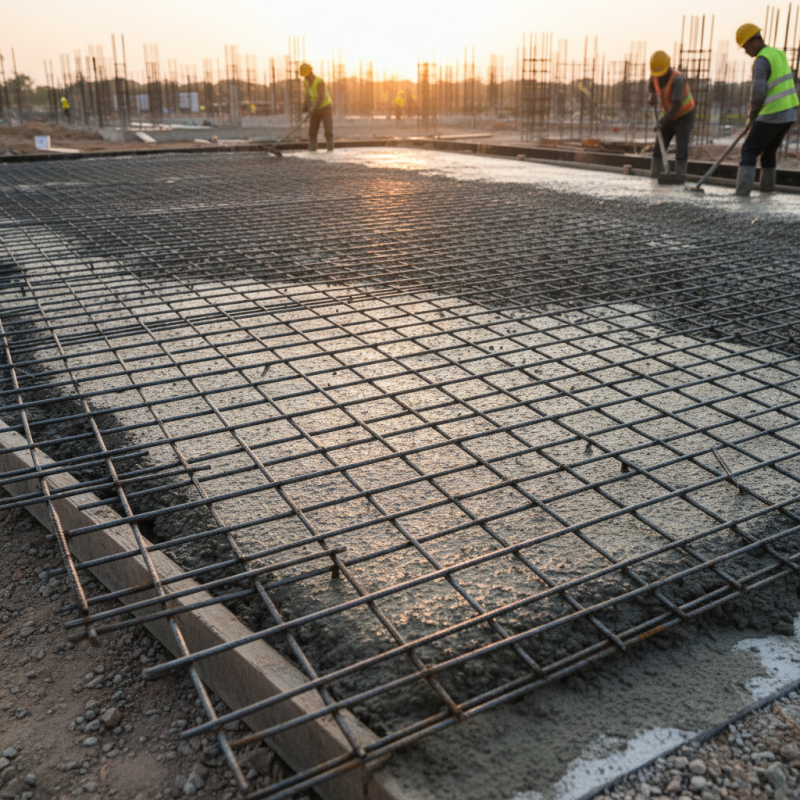

welded wire mesh is a vital component in construction. It consists of steel wires welded together to form a grid. This grid strengthens concrete and improves structural integrity. According to John Smith, a leading expert in construction materials, “Welded wire mesh provides essential support for various building projects.”

In many applications, welded wire mesh is used in foundations, floors, and even fencing. Its durability makes it an ideal choice for reinforcing materials. The grid structure is efficient, allowing for easier installation and reduced labor costs. However, some challenges exist. If not properly installed, it may not achieve the desired strength.

Additionally, the selection of appropriate gauge and spacing is crucial. Miscalculations can lead to weak points in the structure. Therefore, careful planning is essential. This aspect of construction shouldn’t be overlooked. Welded wire mesh proves invaluable, but it requires expertise to use effectively.

Definition and Composition of Welded Wire Mesh

Welded wire mesh is a versatile material in construction. It consists of a network of wires welded together at intersections. This creates a strong, rigid structure. Typically made of steel, the mesh offers excellent durability. The wires usually feature different diameters, depending on the intended use.

In construction, welded wire mesh is essential for reinforcing concrete. It helps distribute loads evenly, preventing cracks. Additionally, it aids in maintaining the structural integrity of walls and floors. The mesh is used in various applications, from residential foundations to commercial slabs.

Despite its benefits, not all projects benefit from welded wire mesh. Some may find it challenging to cut or customize for unique shapes. Others may worry about corrosion over time, especially in harsh environments. It's essential to weigh these factors before choosing this material.

Manufacturing Process of Welded Wire Mesh

Welded wire mesh is an essential material in construction. Understanding its manufacturing process is vital for its proper use. The process begins with high-quality steel wires. These wires are drawn into various diameters based on design requirements.

Once the wires are prepared, they undergo a meticulous welding process. The wires are arranged in a grid format. Electric resistance welding is often used. This method ensures strong bonds at each intersection. While this technique is efficient, it requires monitoring to maintain quality.

After welding, the mesh is often subjected to further treatments. Galvanization may be necessary to enhance durability. This adds a protective layer against corrosion. However, not all projects prioritize this step. Skipping it can lead to premature wear. Understanding these nuances is important for making informed choices.

Types of Welded Wire Mesh Used in Construction

Welded wire mesh is a versatile construction material. It is made from steel wires that are welded together, forming a grid-like structure. These grids come in various sizes and strengths, tailored for different applications. Specific types include standard welded wire mesh, which is often used in floor slabs and walls, and heavier gauge mesh designed for reinforcing concrete in high-stress areas.

In construction, welded wire mesh offers several benefits. It increases tensile strength and helps distribute loads evenly. Reports indicate that using welded wire mesh can reduce crack formations in concrete by up to 50% when compared to traditional reinforcement methods. This is critical for ensuring the longevity of structures. Additionally, it simplifies the installation process, saving both time and labor costs.

Tips: Ensure you select the right mesh type for your project. Thickness and spacing can greatly impact performance. Regular inspections of installed mesh are also essential to catch potential issues early on. The right preparation and choice of materials can lead to better outcomes. Remember, using the appropriate mesh can prevent costly repairs or replacements in the future.

Welded Wire Mesh Usage in Construction

This chart illustrates the percentage of welded wire mesh used in various construction types. It shows that residential and commercial buildings are the largest consumers, highlighting the material's significance in structural integrity and safety.

Applications of Welded Wire Mesh in Building Projects

Welded wire mesh is increasingly popular in construction due to its versatility and strength. This product consists of wires welded together at regular intervals, forming a grid-like structure. It's used widely in different building applications, especially in foundations and slabs. The mesh provides excellent support and reinforcement.

In building projects, welded wire mesh is often placed in concrete. This integration helps prevent cracking and increases structural integrity. Its use enhances safety during the construction phase. Some builders overlook the importance of quality and specifications. They may choose cheaper alternatives, resulting in weaker structures. It's crucial to consider the mesh's gauge and spacing.

Welded wire mesh also finds use in fencing and security applications. It’s common in residential and commercial properties. However, not all installations are perfect. Rust and deterioration can be issues over time. Builders should think about maintenance and proper installation techniques. These factors can greatly influence performance and longevity.

Advantages of Using Welded Wire Mesh in Construction

Welded wire mesh is widely used in construction due to its numerous advantages. One key benefit is its strength and durability. According to a recent industry report, structures that utilize welded wire mesh can withstand significant loads. This is essential for reinforcing floors, walls, and other critical elements. The mesh provides uniform support, which reduces the risk of structural failure over time.

Another advantage is its cost-effectiveness. The production process for welded wire mesh is efficient. This can lead to lower material costs compared to traditional reinforcement methods. Some studies suggest that using welded wire can reduce labor expenses by as much as 15% since it is easier to install. However, some contractors still express concerns about the potential for corrosion if proper protection measures are not taken.

Welded wire mesh is also versatile. It can be adapted for various construction projects, from residential buildings to large-scale infrastructures. Its applications range from concrete slabs to masonry walls. Even so, it is important to note that not all projects will benefit from this material equally. Each construction scenario must be evaluated on a case-by-case basis.

What is Welded Wire Mesh and Its Uses in Construction? - Advantages of Using Welded Wire Mesh in Construction

| Dimension | Material | Use Case | Advantages |

|---|---|---|---|

| 4' x 10' | Galvanized Steel | Concrete Reinforcement | High tensile strength, corrosion resistance |

| 5' x 10' | Stainless Steel | Flooring Support | Durability, aesthetic appeal |

| 3' x 6' | Vinyl Coated Wire | Garden Fencing | Weather resistance, decorative options |

| 6' x 20' | Mild Steel | Structural Support | Cost-effective, easy to install |

| 2' x 4' | Cold-Rolled Steel | Animal Enclosures | Flexibility, lightweight |