How to Adjust a Saw Swing for Better Precision?

When working with a saw-swing, precision is paramount. Proper adjustments to the swing can greatly enhance your cutting accuracy. A well-calibrated saw-swing reduces errors, improves safety, and boosts overall efficiency. Many users overlook this crucial aspect, leading to frustrating results.

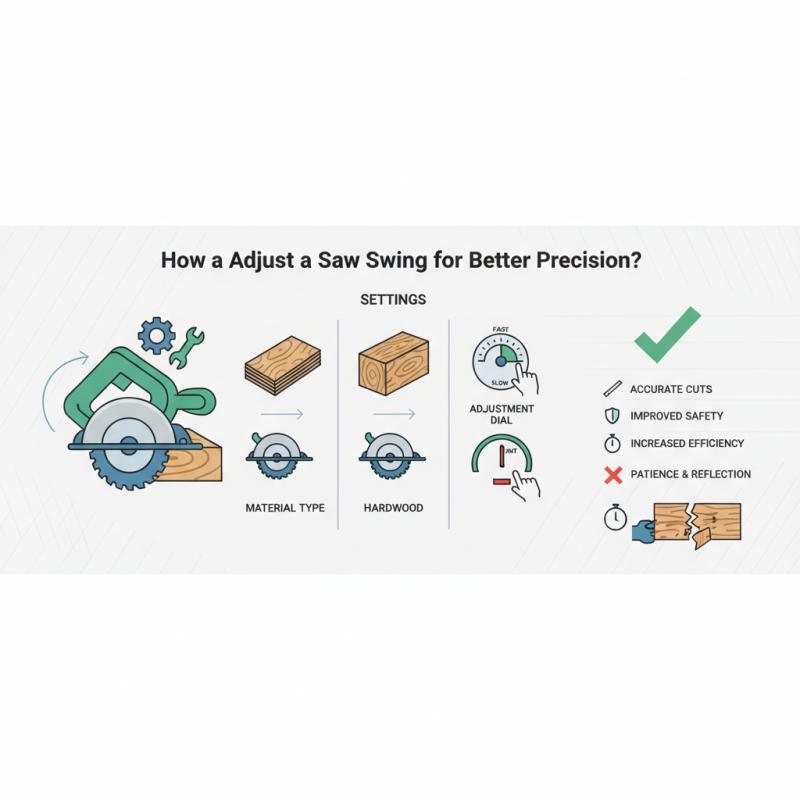

To achieve the best performance, it’s essential to understand the mechanics of your tool. Every saw has specific settings that dictate its swing. These settings should be adjusted based on the material being cut. For instance, plywood requires a different swing than hardwood. Not adjusting for these differences can result in uneven cuts and wasted materials.

Mistakes happen. Many woodworkers ignore the importance of fine-tuning the saw-swing. They may rush through adjustments, thinking it won't make a difference. This mindset can lead to poor cuts and increased frustration. Taking the time to reflect on your technique can yield better results. A little patience goes a long way in achieving precision with your saw-swing.

Understanding Saw Swing and Its Impact on Cutting Precision

Understanding saw swing is crucial for achieving precision in cutting tasks. Saw swing refers to the arc of movement created by the blade as it operates. Subtle deviations can significantly impact the accuracy of cuts. For instance, a study found that a mere one-degree change in swing can lead to misalignment, resulting in up to 3% variance in cut dimensions.

Moreover, precision is not just about the saw itself. You must consider the material being cut. Softwood and hardwood respond differently to blade movements. According to industry reports, misalignment in cutting hardwood can cause up to 25% more tear-out. This might lead to additional time spent on sanding or correcting errors, thus affecting overall efficiency.

Adjustments to saw swing can be tricky. One must calibrate the machine with care. Over-tightening or under-tightening can lead to issues. Many operators overlook this detail, resulting in frustrating outcomes. Continuous learning is essential. Reflecting on past mistakes can guide you toward better techniques and improved precision in future projects.

Key Factors Influencing Saw Swing Adjustment Techniques

When adjusting a saw swing, several key factors come into play. The alignment of the saw blade directly affects the precision of your cuts. If it's misaligned, even the best adjustments won't help. Regularly check the blade for wear and damage. A worn blade can lead to inaccuracies.

Tips: Always measure twice before making cuts. Small adjustments can make a big difference.

The weight distribution on your saw also matters. An uneven setup can cause the saw to tip and sway. This instability leads to imprecise cuts. Adjust the stand for a level base. If you notice wobbling, reassess your setup.

Tips: Use a spirit level to confirm the saw's alignment. This small tool can save you from significant errors.

Moreover, the cutting speed impacts the quality of the swing. If you're cutting too fast, the saw may jump or bind. Slow down and focus on control. Remember, precision takes patience. Each adjustment is a step toward better results.

How to Adjust a Saw Swing for Better Precision? - Key Factors Influencing Saw Swing Adjustment Techniques

| Adjustment Factor | Impact on Precision | Recommended Action |

|---|---|---|

| Blade Alignment | Incorrect alignment can lead to uneven cuts. | Regularly check and adjust alignment as needed. |

| Swing Angle | Affects the ease of control and cut accuracy. | Test different angles for optimal user comfort. |

| Blade Type | Different blades suit different materials; wrong type can hinder precision. | Use the appropriate blade for the specific material. |

| Feed Rate | Too fast or slow can impact cut quality. | Adjust feed rate to match the material being cut. |

| Maintenance | Poorly maintained saws lead to reduced precision. | Implement a regular maintenance schedule. |

Step-by-Step Guide to Measuring Optimal Saw Swing Angles

Adjusting a saw swing for better precision involves careful measurement of angles. Start by placing the saw flat on a sturdy surface. Measure the current swing angle with a protractor. Note any inconsistencies. It’s common to find angles that are off by a degree or two. A small error can lead to major mistakes in cutting.

Next, it's useful to outline the optimal swing angles for your project. Mark specific points on the saw’s base. This helps to visualize your adjustments. Carefully twist the adjustment knob. Make minor changes, then check the swing angle again. You may notice that it still isn’t quite right. That’s okay. Precision takes time and practice.

After making adjustments, perform a test cut. Observe the results. If the cut isn't straight, return to the angle measurements. You might have overlooked a detail. Keep refining the angles until you're satisfied. These incremental changes can lead to better accuracy over time. Embrace the process, acknowledge setbacks, and strive for improvement.

Industry Standards for Precision Saw Swing in Professional Settings

In professional settings, precision is critical for saw swings. Industry standards vary, but most require an accuracy of ±0.5 degrees. This level of precision ensures clean cuts and efficient workflows. However, achieving this can sometimes feel elusive. Factors like blade type and material can influence outcomes.

Adjusting saw swing involves meticulous calibration. Misalignment can cause significant quality issues. Many operators overlook the importance of regular checks. A slight nudge in the swing can lead to errors. Operators should periodically re-evaluate their adjustments, aiming for that perfect balance. It helps to have a keen eye and use reliable measuring tools.

Experimenting with different settings is encouraged. It’s okay to make mistakes along the way. The journey toward precision often teaches valuable lessons. Reflecting on previous cuts can reveal patterns. Some adjustments won't yield expected results but can lead to better insights. Embracing imperfection in this process fosters growth and skill development.

Precision Saw Swing Adjustments

This chart illustrates the relationship between the degree of swing adjustment and the corresponding precision measured in millimeters. As the adjustment degree increases, the precision of the saw improves, leading to more accurate cuts in professional settings.

Common Mistakes in Saw Swing Adjustment and How to Avoid Them

Adjusting a saw swing requires attention to detail and understanding of common mistakes. One frequent error is not aligning the saw blade properly. This misalignment can lead to uneven cuts. Check the saw blade frequently for any deviations. An easy way to ensure accuracy is by using a straightedge.

Another mistake is failing to secure the material properly. If the workpiece shifts during cutting, it affects the precision. Clamping the material down helps maintain stability. Ensure the clamps are tight but not overbearing. If the clamps leave marks, consider using protective pads.

Lastly, many overlook the importance of practice. A saw swing may feel comfortable, yet small adjustments can greatly enhance performance. Spend time experimenting with different angles and setups. Reflect on what works and what doesn't. Learning from these experiences is key to achieving better precision in your cuts.